Our goal and commitment is to deliver innovative solutions

for personal hygiene, medical and industrial markets.

We will meet with our mission by providing reliable,

unmatched superior support and products.

Our core competence is;

we focus innovation on films and composites for medical

and hygiene industries

FELIX - Eskisehir Industrial zone

* Nonwoven and Film production

* Polymer processing

* Printing

* lamination

* converting

Felix Nonwovens Group

• Foundation: 2005-2006

• 7,000 sqm of Owned Area in Eskisehir industrial zone-TURKEY-5000 sqm covered

o 30 people included skilled technicians with long experience in the specific

field of Nonwovens production and converting of these goods.

• 2.000 sqm Converting facility In Izmir for converting and setrilization of Surgical

gowns and Surgical drapes

• 7.000 sqm Converting factility in Fatsa for converting disposable coveralls.

• Modern equipment.

• EN 13795 / EN 13485 /ISO 9001

• FDA

• CE 0120 TYPE III/TYPE IV CATEGORY 3

Products and services offered by Felix:

* Micro embossed films

* Micro porous films

* Spunbond Nonwovens

* Laminated Spunbond nonwovens with films TNT

* Medical substrates

* Industrial substrates and laminates

* Personal protective coveralls and fabrics

* Agriculture frost blankets and mulch film

* Geotextiles

* Filtration and isolation Nonwovens , films and

Laminates

• FILMS- Micro porous/Micro embossed films are formed

with micro pores that enable water vapor molecules and air

to pass through, yet it restricts liquid flow.

• Micro porous films are used extensively in hygiene industry

as the back sheet layer of modern baby diaper. The main

benefits are;

• Soft touchBreathability : The breathability of the film

enables to comport the baby via eliminating unwanted

secretions of liquid vapor

• Non-plastic feeling

• General specifications and range of films:

• Film Weight : 14 - 50 g/m2 WVTR : 500 - 9.500

grams/m2/24hr (ASTM E96-2000 Desiccant)

Medical hydrophilic substrates for drapes

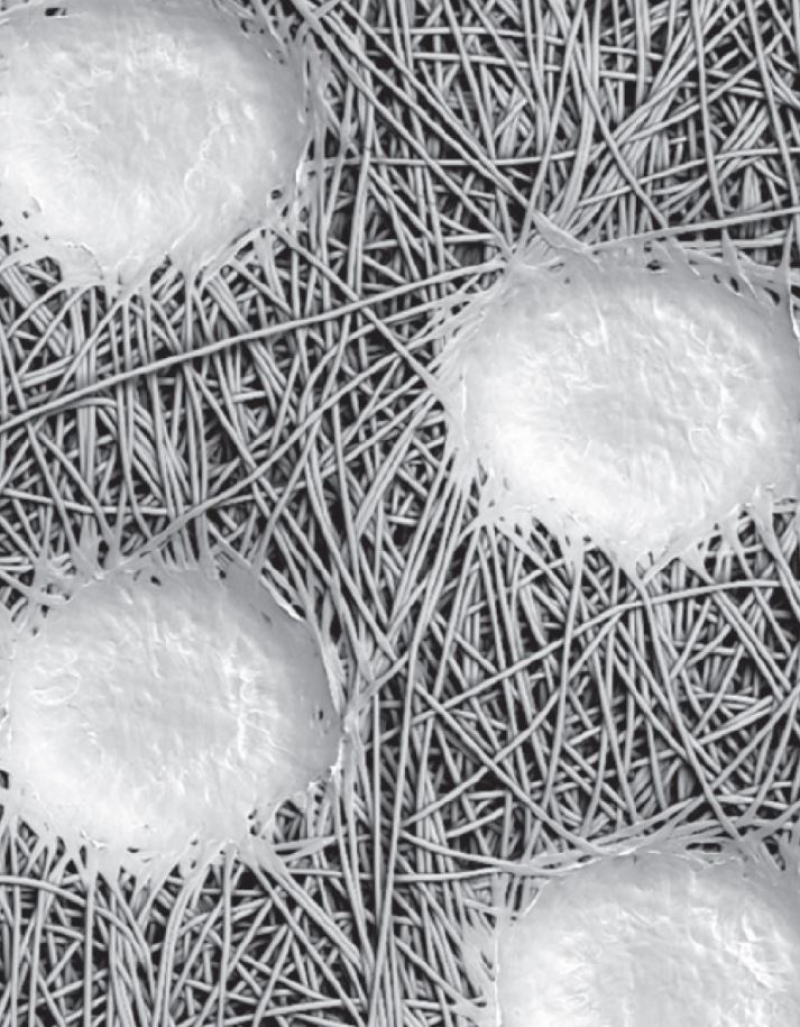

We provide a wide range of nonwoven products for medical sector. The raw materials we develop and manufacture

are considered as the innovation leader in the market. We develop and manufacture spunbond nonwovens, film, laminated

products for disposable drapes, gowns and disposable surgical sets. Our spunbond nonwoven products are used in

products such as disposable drapes, gowns, visitor’s gowns, doctor caps, galoshes and masks. Our custom designed and

manufactured products of disposable drapes; Spunsper54 (spunbond biflex) and Spunsper63 (spunbond triplex) are used

as a disposable drape/compress in end-use surgeries. In addition, medical laminated products for A Class segment are

manufactured with our Viscose Biflex and Viscose triplex barrier and breathable film laminated products.

The standards regarding surgical fabrics are determined by EN 13795 and AAMI. Based on these standards, the drapes

are categorized as per their classes and minimum requirements are set for each class. High performance and 4th level

viral barrier products provide the top-quality protection.

Surgical fabrics keep patients and healthcare personnel from transmitting infection

FULL BODY COVER/ PARTIAL BODY COVER- BODYGARD

Fullbody covers and partial body covers are new generation temprorary

paint and dent protection for cars

Breathable / Bariyer film; Water proof: water

column > 190cm

Nonwoven is water repellent (hydrophobic)

Resistant to chemicals (tree resins, oils, etc.)

*UV resistant, up to 12 months

*Resistant to salt-laden sea air (sea transport)

HFPO FILM/ WET WIPE PACKAGING/ GRAIN & FLOUR PACKAGING / BUTTER PACKAGING/

SOAP PACKAGING

HFPO® film has a paper-like feel and superior foldability and printability. It is also oil- and waterresistant.

Compared with pure polymers, HFPO® Film is twice as effective a barrier to light and

water vapour. This means that the HFPO® films can replace more complex laminate solutions

such as PE/Paper. One major advantage is that moderately filled HFPO® Film has considerably

improved tear-resistance and dart drop

Increased Output, better Profitability

HFPO® is made from the polymers PP (polypropylene) or PE (polyethylene), to which we add

natural mineral in various degrees of fineness to create a material with outstanding

performance. Our HFPO® material is available as as processed film.

HFPO® is environmentally harmless. It is also grease and waterproof. FPO® is used today in

many different areas, from manufacturing and printing to the food industry. The compound as

well as the film have EU and FDA approval for use with foodstuff

Fatsa Facility

Converting production

facility is based on a

6.215 m² net area in an

Industrial Park at Fatsa/

Ordu (North-East part of

Turkey).

This facility has 10

different production

lines

Research and development

• Super hydrophobic SURFACES

• Direct extrusion systems for spunbond and

film production

• Anti-MICROBIAL films and Nonwovens

• Super hydrophilic spunbond nonwovens

• Flame Retardant Nonwovens

• UV stabilized Nonwovens and films

• At Felix we are committed to achieve superior quality standards. We

understand your requirements and deliver products and services that

surpass your expectations.

• We continually improve and innovate in the products and services via

utilizing every possible mean of technological advancements.

We maintain quality standards of products and services through constant

evaluation, inspection and verification at all stages.