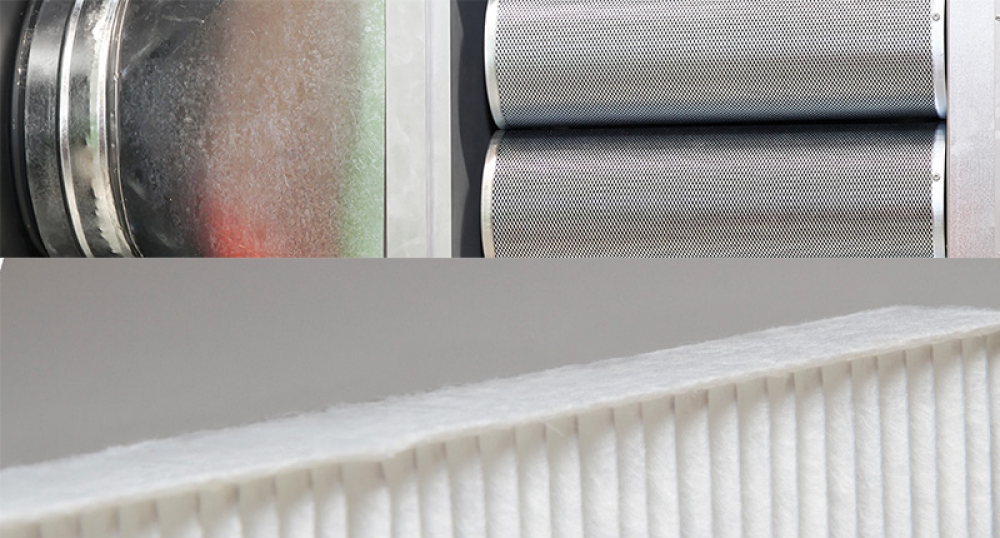

Nonwoven fabrics are used in powder sacks and air filter and oil and other liquid filters due to breathable, powder and particle proof and heat-resistant and durable features, respectively.

Among textile materials, specifically weaved and nonwoven fabrics are apt for filtration application owing to complex structure and appropriate thickness.

The Advantages of nonwoven fabric filters over weaved fabric filter:

• High permeability

• High filtration yield

• Low bending tendency

• No thread dislocation observed in weaved fabrics

• No leakage [1]

Compared to fabrics weaved with metal material and monofilament weaved fabrics, nonwoven fabrics have more thick edge and volume. Therefore, nonwoven fabrics are preferred when general sterilization of high number of particles loading, long life time or liquid or gas flow is required.

The Recent developments of filtration materials are as follows:

• Fineness of fiber

• Molding and laminated filtration systems

• Functioned filtration systems

The Application of nonwoven filter in technique textile

• Home technique textiles (vacuum cleaner filters, air filters)

• Health technique textiles (face masks)

• Forwarding technique textiles (oil, air, pollen and petrol filters)

• Protection technique textiles (nano-masks for SARS and H5N1 viruses)

• Packaging technique textiles (coffee filters, tea bags) and ‘baghouse’ filtration with needle-felted nonwoven fabrics- See more at:

Spunbond nonwoven fabrics:

-support of cooling filtration, cartridge pleat and membrane, retarding feature of material flow

-they are probably the most multifunctional fabrics with layers, sacks, pool and spa and many more filter types. These filters provide strength, reasonable dust holding capacity, rigidness in specific occasions and lateral permeability.

-Popularity air filter of nonwoven fabrics has been increasing for applications requiring HVAC and high yield.