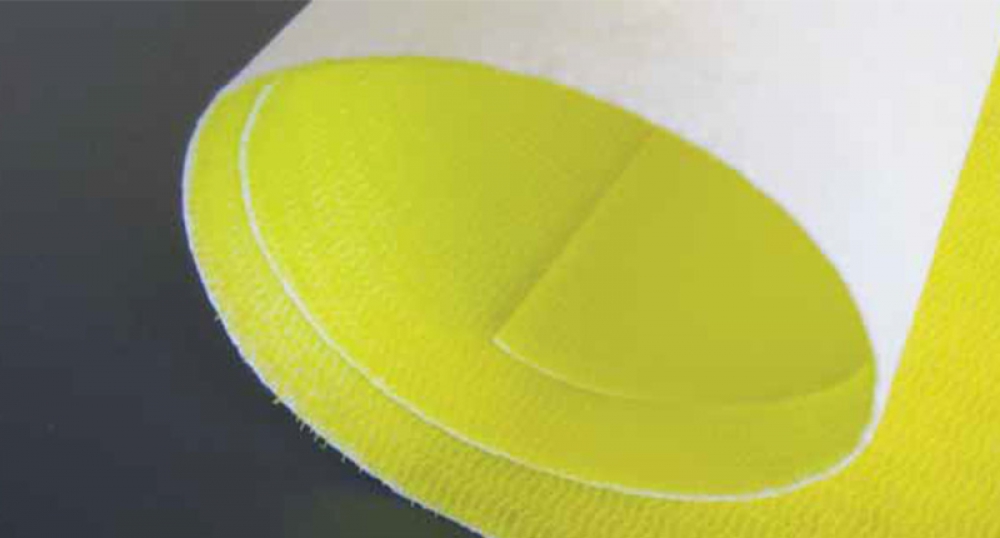

Engineered nonwovens designed for composite industry. Newly-developed for infusion process users, the product can provide flow control without affecting or decreasing the rate. As it is easily separable following resin infusion molding, it requires less material consumption and less workmanship. It is also easily separable with release film and breather fabric of PRE-PREG and hand molding.

IZOTEX and SUPERFORM products have breathable and micro-mesh feature that you can use resin infusion. As it is used as only one layer, it decreases the usage of conventional two to three layer materials.

In resin infusion process, dry fiber materials (e.g. fiberglass/carbon fiber/Kevlar fiber/ flexten fiber etc.) are directly placed in mold. A distribution fabric or a mesh-shaped plastic is also used for correct distribution. A peeling material is needed to function as a separator between dry fiber material and resin distribution fabric. IZOTEX and SUPERFORM products refer to separator peeling material or resin distribution fabric. They function as a sole separator and resin distribution fabric processed by two to three layers. They are an ideal solution for resin infusion process.

IZOTEX and SUPERFORM products are used as distribution fabric or a mesh-shaped plastic in PRE-PREG and Vacuumed sack processes for correct distribution. A peeling material is needed to function as a separator between dry fiber material and resin distribution fabric. IZOTEX and SUPERFORM products refer to separator peeling material or resin distribution fabric. They function as a sole separator and resin distribution fabric processed by two to three layers. They are an ideal solution for resin infusion process.