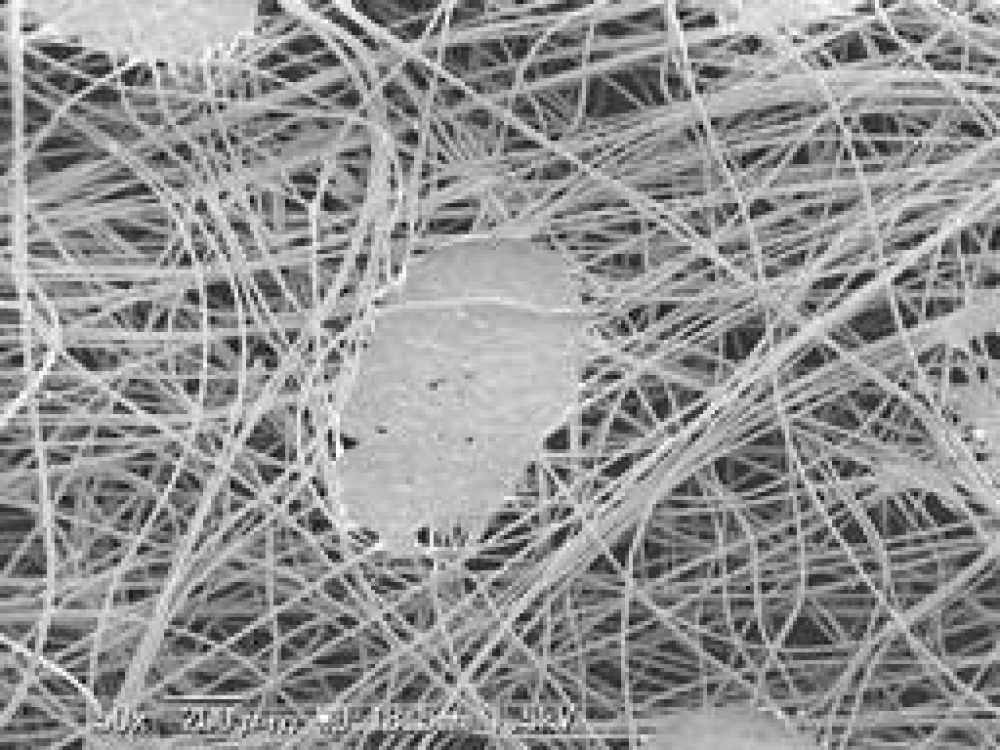

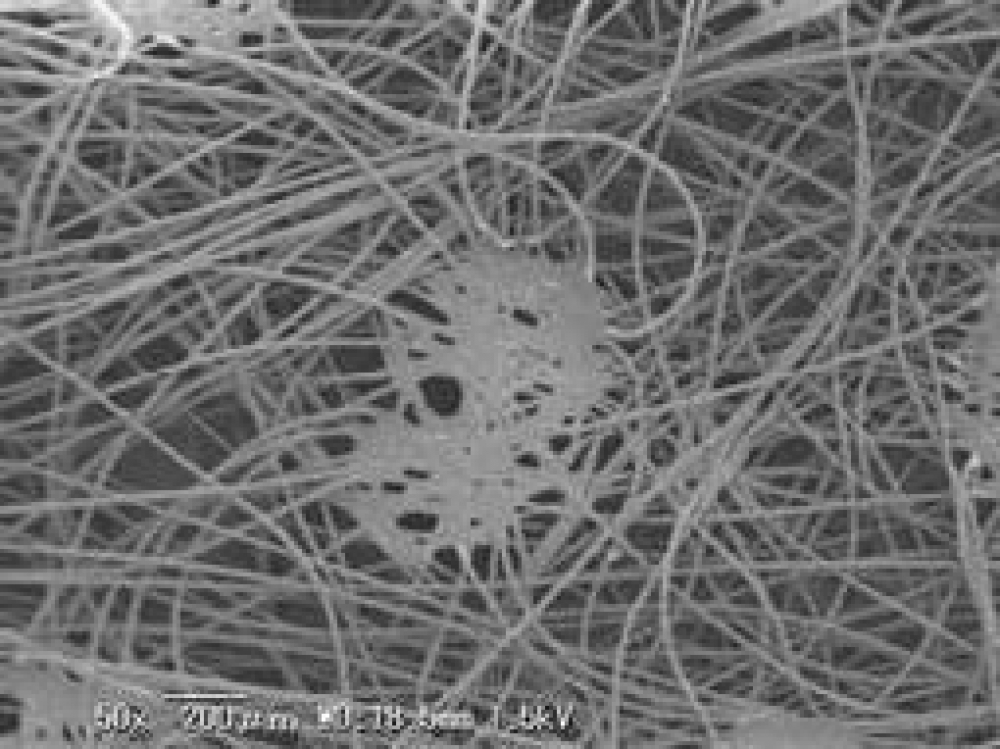

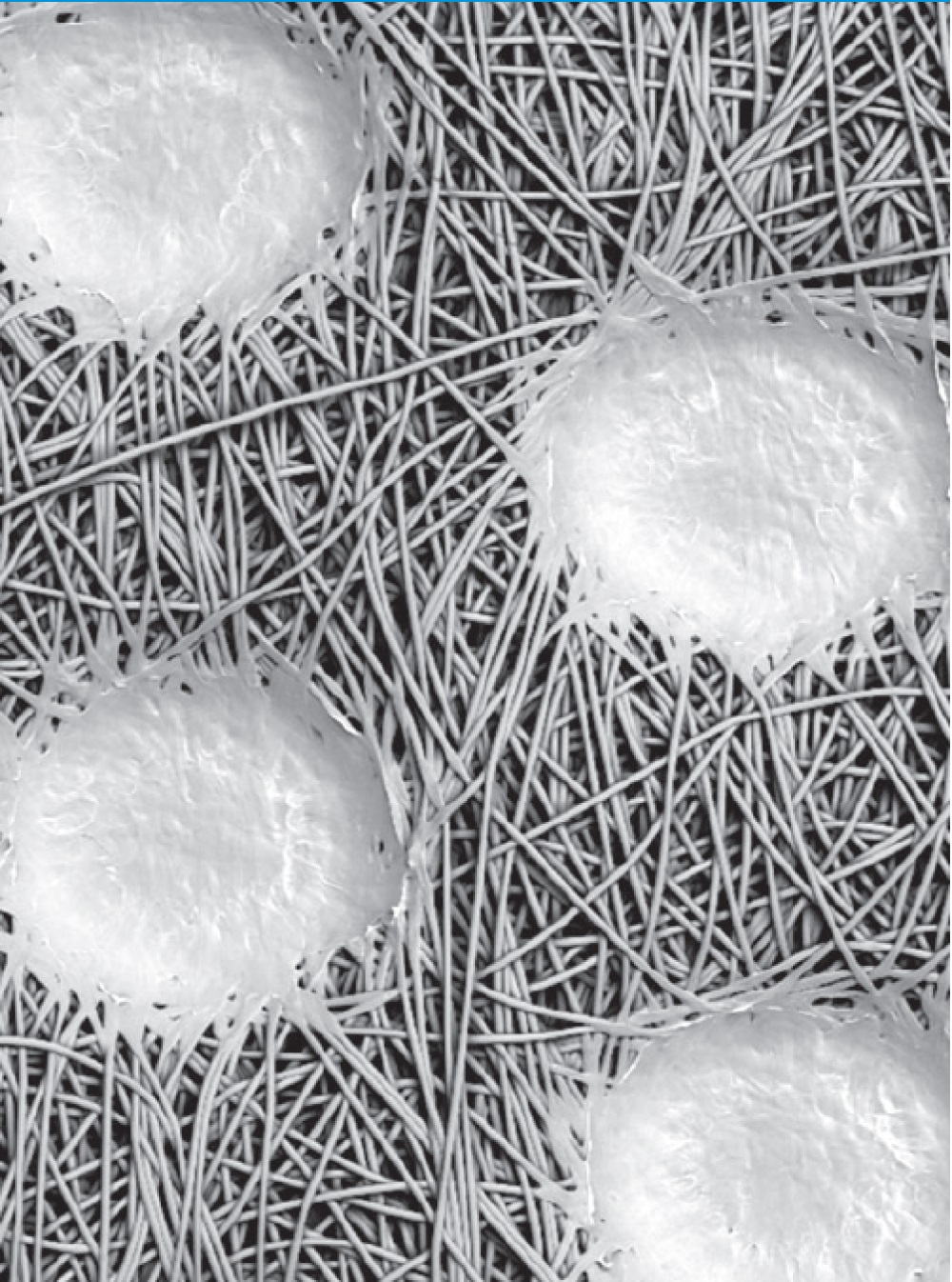

Spunbond Nonwoven

Spunbond nonwoven, Polyproplyene spunbond production technology has rapidly developed and replaced in the last 20 years for the technical textile and non-woven fabric industry. Polyproplyene is produced in the form of granulation of the raw material by melt extrusion method and filaments. The nature of the production of spunbond nonwoven fabric is based on the direct rotation of the continuous filaments of the polymeric granules and the subsequent nonwoven fabric being manufactured.

The basic qualities of the spunbond nonwoven product include:

Spunbond surface density range is approx. 10 - 150 g / m2

100% polypropylene spunbond nonwoven content

Equal distribution of fiber in the surface fabric, which determines approximately the characteristic characteristics. 2: 1 in longitudinal and transverse direction

High final strength of the fabric due to the high strength of continuous filaments (filaments)

Spunbond nonwoven, spunbond fabric

1.6 meter net width

12 - 150 g / m2 (0.35 to 4.5 oz / yd2) weight ranges,

100% polypropylene (PP) thermally produces sesame (non-woven) nonwoven materials.

Spunbond nonwoven, spunbond fabric products can be extended to the outside environment against UV rays and ultraviolet protection.

Spunbond non woven, spunbond fabric products can be given as absorbent or repellent. Absorbent spunbond fabrics are expected to be above the 2 seconds of absorbing liquid. Similarly, spunbond nonwoven products which are repellent are expected to be liquid resistant at least 60cmH2o2 column test. Absorbent or repellent spunbond nonwoven products are generally used in medical industrial products, disposable operating room covers, patient visitor fabrics, and doctor dresses.

Spunbond nonwoven products can produce burners as a burner. The switching of combustion is produced as DIN 4102, FMVSS 302, ISO 4589-1, EN 13984, EN 13859 and most importantly FR = Fire retardant, EN 13501-1 fire class B2.