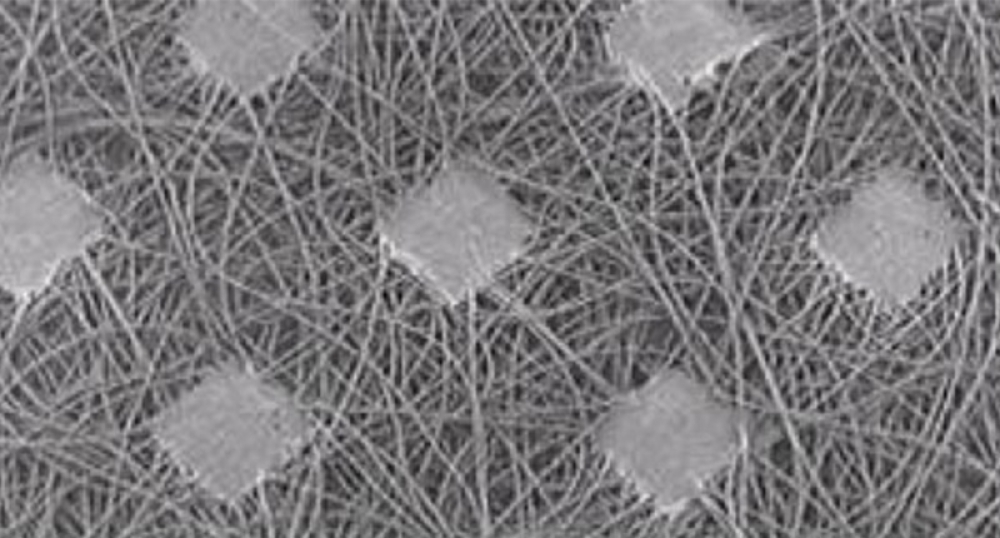

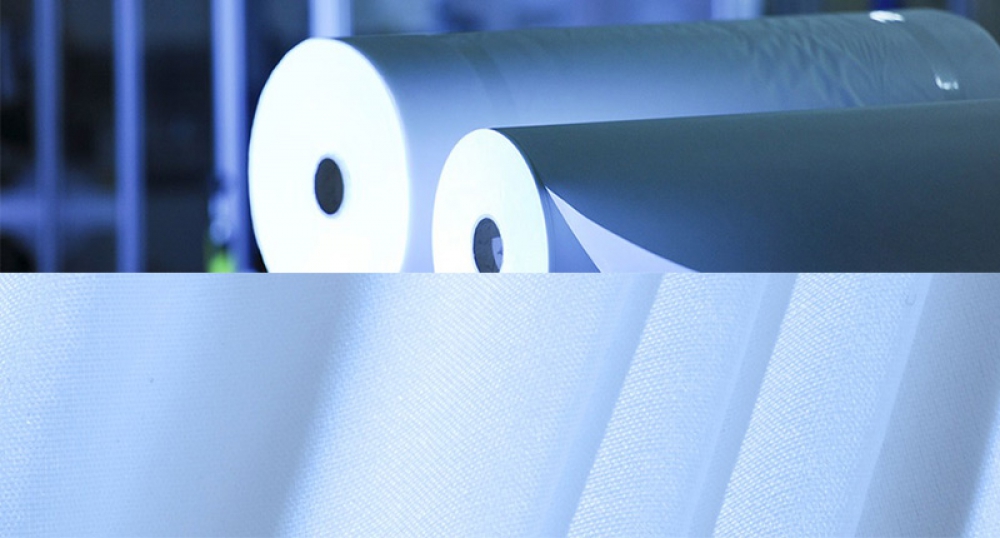

Felix nonwovens produces %100 Polypropylene (PP) spunlace, thermal sesame, spunbonded nonwoven fabrics with a width of up to 1.6 m. and a weigh of 12-150 gr/m^2 (0.35 to 4.5 oz/yrd^2). It can be optimized for special needs due to its different fiber intensity and available fabric types. The thinness of the filament, dpf (denier per filament) is one of the most important factors that effects the performance and the feature of the fabric. Depending on the desired performance, fabrics can be produced within the range of 1 to 4 denier per filament.

When extraordinary entanglement and homogeneity is required the multiple layer, bond together nonwoven technology can be used. The balance between softness and MD/CD tensile strength is a solution successfully attained by Felix Nonwoven.

It can be produced with specific features using additives, such as surface applications:

- Hydrophilic fabrics

- UV resistant fabrics

- Fire-retardant fabrics

- Antistatic fabrics

- Antibacterial fabrics

- Luminous fabrics

- Colorful fabrics